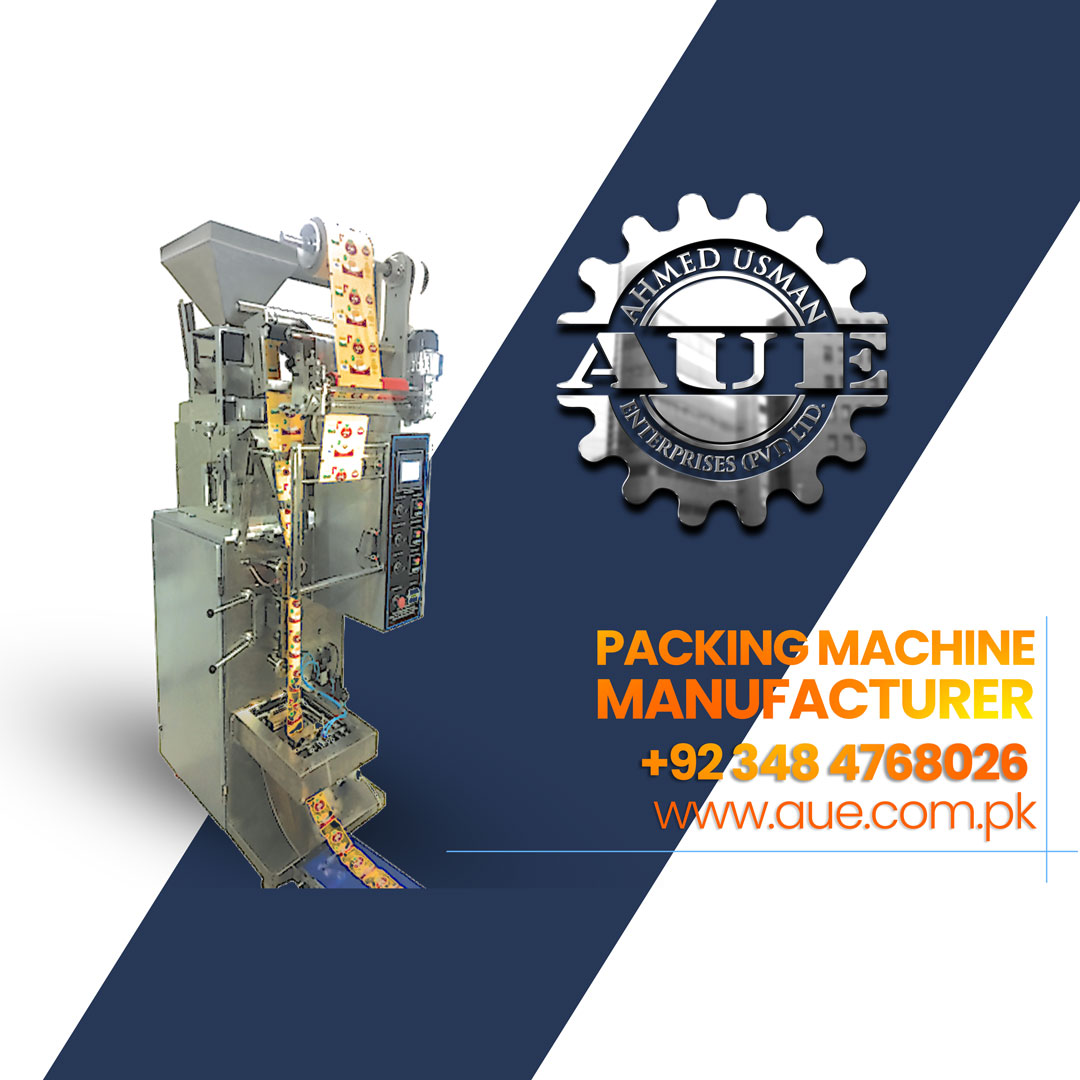

Automatic Clip Sealing & Packaging Machine

September 10, 2022

Packing Machined Needs

March 14, 2023Oil Packing Machine

Automatic form-fill-seal machine for packing of liquid products e.g. Fresh Milk, Fruit Juices, Water, Cooking Oil and Vegetable Ghee etc.

-

CAPACITY

100 to 1000 ml/grams -

BAG SHAPE

Pillow shape, side seal, centralized design. -

DIMENSIONS

2300 x 730 x 900 mm (HxWxD) -

POWER SUPPLY

220/380 V, 3 Phase, 50 Hz. -

SPEED

Ghee 1000g 2400, 500g 3600, 250g 4800 (Pouch/p/Hour) Oil 1 Ltr. 2000 (Pouch/P/Hour) -

WEIGHT

500 Kgs (Complete Unit)

In the dynamic landscape of the packaging industry, the demand for efficient and reliable solutions has led to the development of cutting-edge technologies. Automatic form-fill-seal machines have emerged as indispensable tools, particularly in the realm of liquid product packaging. This comprehensive guide explores the features, specifications, and advantages of an advanced automatic form-fill-seal machine designed for packing liquid products such as fresh milk, fruit juices, water, cooking oil, and vegetable ghee. This machine is not only versatile in its application but also boasts a range of features that make it an ideal choice for manufacturers. Let's delve into the intricacies of this innovative piece of equipment.

Introduction to Automatic Form-Fill-Seal Machine

Definition and Functionality

An automatic form-fill-seal machine is a state-of-the-art packaging solution that integrates the processes of forming, filling, and sealing into a seamless operation. This particular machine is designed specifically for packing liquid products, addressing the unique challenges posed by substances such as fresh milk, fruit juices, water, cooking oil, and vegetable ghee. The automation of these processes enhances efficiency, reduces human intervention, and ensures precision in packaging.

Key Applications

The versatility of this automatic form-fill-seal machine makes it suitable for a variety of liquid products. Some of the primary applications include:

-

Fresh Milk Packaging: The machine accommodates packaging requirements for fresh milk, maintaining the product's freshness and extending its shelf life.

-

Fruit Juices: Whether it's a smoothie or pure fruit juice, the machine efficiently packs liquid products with precision and speed.

-

Water Packaging: With the growing demand for packaged water, this machine facilitates the packaging of water in various sizes, catering to consumer preferences.

-

Cooking Oil: The machine is adept at handling the viscosity of cooking oil, ensuring spill-free and efficient packaging.

-

Vegetable Ghee: The packaging of vegetable ghee, a crucial ingredient in many cuisines, is streamlined with this automated solution.

Technical Specifications

Capacity

The machine is designed to handle a wide range of liquid volumes, ranging from 100 to 1000 ml/grams. This flexibility allows manufacturers to cater to diverse market needs with a single machine.

Bag Shape

The automatic form-fill-seal machine offers multiple bag shapes to suit different packaging requirements. The available options include pillow shape, side seal, and centralized design, providing manufacturers with the versatility needed for various product presentations.

Dimensions

The compact design of the machine is optimized for space efficiency, measuring 2300 x 730 x 900 mm (HxWxD). This allows for easy integration into existing production lines while minimizing the footprint of the equipment.

Power Supply

The machine operates on a power supply of 220/380 V, 3 Phase, 50 Hz. This power configuration ensures stability and reliability during the packaging process, contributing to consistent and high-quality output.

Speed

One of the standout features of this automatic form-fill-seal machine is its impressive speed. The machine can pack vegetable ghee at 1000g with a speed of 2400 pouches per hour, 500g at 3600 pouches per hour, and 250g at 4800 pouches per hour. For oil packaging in 1-liter quantities, the speed reaches 2000 pouches per hour. This high-speed performance significantly enhances production efficiency, meeting the demands of fast-paced manufacturing environments.

Weight

The complete unit of the automatic form-fill-seal machine weighs 500 kgs. Despite its robust construction and advanced capabilities, the machine remains relatively lightweight, simplifying installation and repositioning within the manufacturing facility.

Advantages of Automatic Form-Fill-Seal Machine

1. Precision and Accuracy

The automated nature of the machine ensures a high level of precision and accuracy in forming, filling, and sealing processes. This minimizes product waste and ensures that each package meets quality standards consistently.

2. Versatility in Packaging

The machine's ability to handle a diverse range of bag shapes and liquid volumes makes it a versatile solution for manufacturers dealing with various liquid products. This adaptability is crucial in catering to market demands and staying competitive in the industry.

3. Speed and Efficiency

The impressive speed of the machine translates to higher production output, meeting tight deadlines and addressing market demands efficiently. The efficient use of time and resources contributes to overall cost-effectiveness for manufacturers.

4. Space Optimization

The compact dimensions of the machine make it an ideal choice for manufacturers with limited floor space. The centralized design further enhances space optimization, allowing seamless integration into existing production lines.

5. Reliability in Operation

With a robust construction and a power supply configuration designed for stability, the automatic form-fill-seal machine offers reliable and uninterrupted operation. This reliability is crucial for manufacturers who depend on consistent production cycles.

6. Consistent Seal Quality

The machine's sealing mechanism ensures a consistent and reliable seal for each pouch, preventing leaks and preserving the integrity of the packaged liquid products. This is especially critical for products like cooking oil and vegetable ghee, where proper sealing is essential for maintaining quality.

7. Easy Maintenance

Designed with user convenience in mind, the automatic form-fill-seal machine is easy to maintain. Regular maintenance procedures are straightforward, minimizing downtime and ensuring continuous operation.