AUE Blog

October 18, 2023

Revolutionizing the Industry: A Comprehensive Guide to Cooking Oil Packing Machines

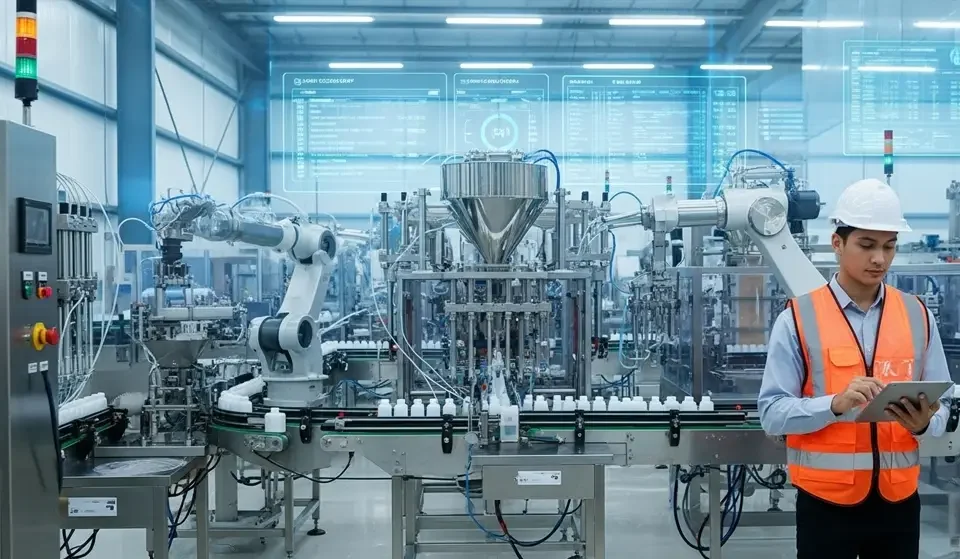

January 11, 2024In the ever-evolving landscape of industrial manufacturing, the role of advanced machinery cannot be overstated. Industrial packing equipment, in particular, emerges as a pivotal player in optimizing efficiency, streamlining processes, and ensuring the seamless packaging of products across diverse industries.

Enhancing Operational Efficiency

Industrial packing equipment stands as the backbone of modern manufacturing operations. Its ability to automate and expedite the packaging process translates to enhanced operational efficiency. By minimizing manual intervention, these machines not only reduce labor costs but also significantly increase production output.

Precision in Packaging

One of the key advantages of industrial packing equipment is its unmatched precision. Whether dealing with fragile goods or items requiring intricate packaging, these machines ensure a level of precision that is hard to achieve manually. This precision not only safeguards the integrity of the products but also contributes to an elevated standard of quality.

Customization for Varied Needs

Versatility is a hallmark of industrial packing equipment. Manufacturers can customize these machines to meet the unique packaging needs of different products. From varying sizes to specialized packaging materials, these machines adapt to the specifics of each manufacturing line, offering a tailored solution for diverse industries.

Cost-Effective Solutions for Businesses

Investing in industrial packing equipment is not just a modernization strategy; it’s a cost-effective solution for businesses. While the initial investment might seem substantial, the long-term benefits, including reduced labor costs, lower error rates, and increased production speed, make it a prudent financial decision.

Sustainability Integration

In an era where sustainability is a top priority, industrial packing equipment plays a vital role in minimizing environmental impact. By optimizing materials and reducing waste, these machines contribute to eco-friendly manufacturing practices, aligning businesses with global sustainability goals.

Adapting to Industry 4.0

The fourth industrial revolution, Industry 4.0, emphasizes connectivity and automation. Industrial packing equipment seamlessly integrates with this paradigm, offering smart solutions that can be monitored and controlled remotely. Real-time data analytics further contribute to predictive maintenance, minimizing downtime and ensuring uninterrupted production.

Choosing the Right Industrial Packing Equipment

Selecting the right industrial packing equipment requires a thoughtful evaluation of specific manufacturing needs. Factors such as production volume, types of products, and desired levels of automation play a crucial role in making an informed decision. Consulting with experts in the field can streamline this process, ensuring a tailored solution for optimal results.

Tags (Comma-Separated): Industrial Packing Equipment, Automated Packaging Solutions, Manufacturing Efficiency, Precision Packaging, Custom Packaging Machinery, Cost-Effective Solutions, Sustainability in Manufacturing, Industry 4.0 Integration, Packaging Automation, Smart Manufacturing, Industrial Revolution, Eco-Friendly Packaging, Production Optimization, Packaging Technology, Manufacturing Innovation, Tailored Packaging Solutions, Machinery Efficiency, Advanced Manufacturing, Smart Industry, Packaging Solutions