Surf Detergent Powder (Back Seal Bag) Packing Solution.

February 28, 2024

Efficiency Unveiled: The Harpic Bottle Packing Machine and Its Advantages

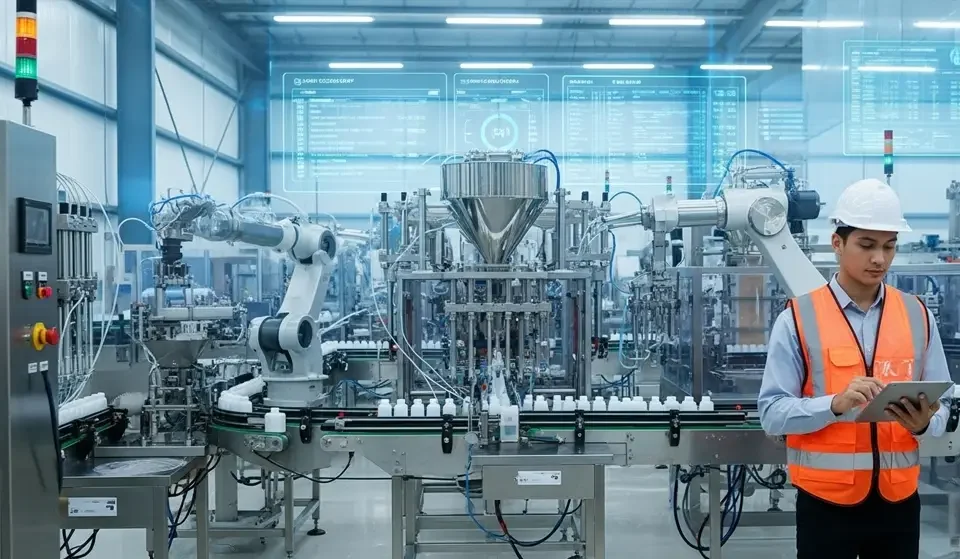

March 4, 2024Discover the efficiency and versatility of a liquid filling machine designed to streamline filling operations. Explore its features, and benefits, and understand how it enhances productivity and accuracy in various industries. From user-friendly operation to customizable options, uncover the details that make this machine a valuable asset for your business.

Explore the efficiency and versatility of a liquid filling machine designed to streamline filling operations. Learn about its features, and benefits, and understand how it enhances productivity and accuracy in various industries.

Key Features:

- Automated liquid filling for increased efficiency.

- Versatile design accommodates a wide range of liquid products.

- User-friendly interface ensures ease of operation.

- Precise filling mechanisms ensure accuracy and consistency.

- Durable construction for long-term reliability.

- Customizable options to meet specific production needs.

- A compact footprint saves space in production facilities.

Benefits:

- Improved productivity and efficiency in filling operations.

- Reduced product waste and spillage.

- Enhanced accuracy and consistency in filling quantities.

- Cost-effective solution with low maintenance requirements.

- Streamlined production processes for increased output.

- Adaptability to diverse liquid products and packaging requirements.

Applications:

- Food and beverage industry for filling liquids such as sauces, syrups, and beverages.

- Pharmaceutical industry for filling medications, syrups, and oral solutions.

- Cosmetic industry for filling creams, lotions, and serums.

- Chemical industry for filling solvents, detergents, and cleaning solutions.

- Agricultural industry for filling fertilizers, pesticides, and liquid supplements.

Technical Specifications:

- Filling Method: [Specify the filling method, e.g., Volumetric Piston Filling, Gravity Filling, etc.]

- Filling Capacity: [Specify the filling capacity, e.g., 100 ml to 1000 ml]

- Speed: [Specify the speed, e.g., 500-600 bottles per hour]

- Filling Accuracy: [Specify the filling accuracy, e.g., +/- 0.5%]

- Material: [Specify the construction material, e.g., Stainless Steel (S.S)]

- Power Supply: [Specify the power supply requirement, e.g., 220V/50Hz]