Revolutionizing the Industry: A Comprehensive Guide to Cooking Oil Packing Machines

January 11, 2024

Enhancing Packaging Efficiency with the Automatic Clip Sealing Machine

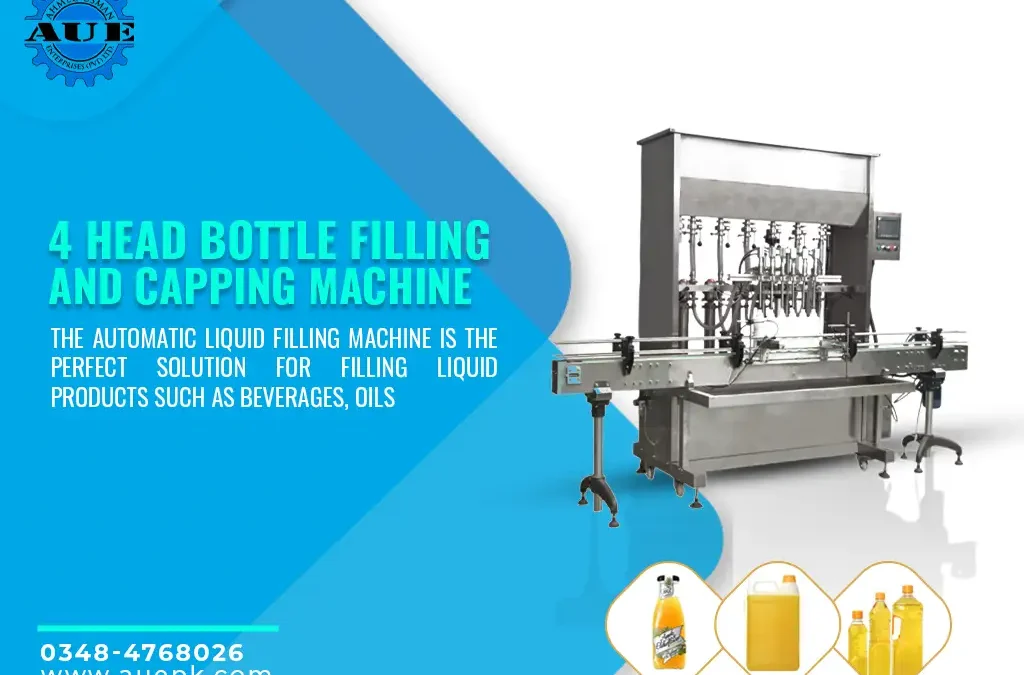

January 17, 2024In the ever-evolving landscape of manufacturing, efficiency and precision are paramount. Industries dealing with liquid products, such as beverages, pharmaceuticals, and chemicals, require advanced machinery to streamline their production processes. One such technological marvel is the Four Heads Bottle Filling and Capping Machine, a versatile solution that combines speed, accuracy, and reliability. In this article, we will explore the capabilities of these machines, addressing frequently asked questions (FAQs) to provide a comprehensive understanding of their functionality and benefits.

I. Overview of Four Heads Bottle Filling and Capping Machine

The Four Heads Bottle Filling and Capping Machine is a sophisticated piece of equipment designed to automate the filling and capping processes for bottles. This machine is particularly beneficial for industries dealing with large-scale production, where efficiency is crucial. Let’s delve into the key features that make this machine stand out:

- High-Speed Filling: The machine is equipped with four filling heads, allowing it to fill multiple bottles simultaneously. This results in a significant increase in production speed, reducing the overall manufacturing time.

- Accurate Volume Control: Precision is paramount in industries like pharmaceuticals and chemicals. These machines come with advanced volume control mechanisms, ensuring that each bottle is filled with the exact quantity specified, minimizing wastage.

- Versatile Capping Options: The capping mechanism is designed to accommodate various types of caps, including screw caps, snap caps, and press-on caps. This versatility makes the machine suitable for a wide range of products and industries.

- User-Friendly Interface: Modern Four Heads Bottle Filling and Capping Machines are equipped with user-friendly interfaces, allowing operators to easily set parameters, monitor the production process, and make adjustments as needed.

II. FAQs about Four Heads Bottle Filling and Capping Machines

- Q: What types of bottles can be used with a Four Heads Bottle Filling and Capping Machine?

A: These machines are designed to work with a variety of bottle shapes and sizes, including round, square, and rectangular bottles. The adjustable nature of the machine’s components ensures compatibility with diverse packaging requirements.

- Q: How is the filling volume controlled to ensure accuracy?

A: The filling volume is controlled through precision mechanisms, such as flow meters or piston fillers, depending on the specific model. These mechanisms ensure that each bottle receives the exact volume specified in the production parameters.

- Q: Can the capping mechanism handle different types of caps?

A: Yes, Four Heads Bottle Filling and Capping Machines are designed to accommodate various types of caps, including screw caps, snap caps, and press-on caps. This flexibility makes the machine suitable for a wide range of products and industries.

- Q: How easy is it to clean and maintain the machine?

A: These machines are designed with easy cleaning and maintenance in mind. Components that come in direct contact with the product are often removable and washable. Regular maintenance procedures are straightforward, contributing to the longevity of the machine.

- Q: Can the production speed be adjusted to accommodate different requirements?

A: Yes, the production speed of the machine is adjustable. Operators can set the desired speed based on the specific requirements of the production run, allowing for flexibility in meeting varying demand levels.

III. Benefits of Using Four Heads Bottle Filling and Capping Machines

- Increased Efficiency: The simultaneous filling of four bottles and the high-speed capping mechanism significantly boost overall production efficiency.

- Cost Savings: The automation of the filling and capping processes reduces the need for manual labor, leading to cost savings over time.

- Precision and Consistency: The advanced volume control mechanisms ensure precise filling, maintaining consistency across all bottles in a production batch.

- Versatility: The machine’s ability to handle different bottle shapes and cap types makes it versatile, catering to the diverse needs of various industries.

- User-Friendly Operation: The intuitive interfaces make these machines easy to operate, reducing the learning curve for operators.

IV. Conclusion

The Four Heads Bottle Filling and Capping Machine represents a leap forward in production technology, offering unparalleled efficiency, precision, and versatility. Industries dealing with liquid products can benefit significantly from the streamlined processes and cost savings these machines bring. As technology continues to advance, these machines are likely to play a crucial role in shaping the future of manufacturing.